Doming for Printers

Contract Doming is a service we offer to printers who supply DomeTag with printed labels and stickers. We apply the urethane dome to supplied labels and ship them back to the printer.

At the risk of this sounding like a sales pitch, consider having DomeTag take full responsibility for the printing, cutting, and doming of your doming job. By specializing in just domed labels all of our equipment and supplies are for doming. Our substrates are pre-tested to make sure that they bond to the urethane dome. Our printing inks do not react with the urethane and they are pigmented for outdoor fade-resistance. Our cutting leaves a sharp edge ideal for clean doming edges without cut-through that can cause defects. Our liners are custom ordered to lay flat during the doming process. And our humidity levels are controlled to prevent chemical reactions (bubbles). Our production is consistent and reliable without any finger pointing over defects.

That said, we are happy to dome labels that you supply. Please take a minute to read through some of the special needs for your Contract Doming job – learn more below.

Printing

Most printing methods, inks, and substrates are acceptable. While it is unusual for us to have a chemical reaction it does happen on occasion so you are encouraged to send swatches for testing.

Colorfastness: The clear dome blocks enough ultraviolet light to approximately double the normal fade-resistant life of most prints.

Digital Printing: Most digital printing is suitable for doming; however, there can be a big difference in colorfastness (fade resistance) between digital printers with HP Indigo limited to about one year for full-sun exposure and inkjet printing with pigmented, UV inks being one of the best with about three-year outdoor exposure.

Screen Printing: Screen printing is an excellent print method for most doming applications. There are very few chemical reactions and the inks typically adhere well on films like polyester and vinyl. Also, the flat nature of the screen printing process is a good match for the flat process of doming.

Flexo Printing: Flexo can be a good choice for doming providing that substrates and liner lay flat after sheeting and finish coatings are not used. Use a 90 lb. coated paper liner or polyester liner when possible to avoid curl memory typical of thinner paper liners. Sheet the rolls prior to shipping to avoid curl and consider colorfast, pigmented inks to improve fade resistance.

Offset Printing: As long as the labels are printed on a non-porous surface such as polyester or vinyl, offset printing works great. Be sure to send test swatches to verify adhesion of the cured urethane dome to the print coatings that may be on the print surface. The colors fade a little too fast for outdoor applications; however, offset printing may be a low cost, quality alternative for limited, colorfast life on indoor products.

Laser Printing: We’ve had limited success doming onto polyester films printed on laser printers. Unfortunately, the urethane has a chemical reaction with an acid in most toners. Again, send a sample for us to test.

Other: Send a swatch or sample for us to run a test dome for flow, adhesion, and curing. Some inks, substrates, and coatings are not compatible with doming.

Varnishes and Laminates

Varnishes: Avoid varnishes when possible. Most coatings limit the ability of the urethane to bond to the substrate and may cause the dome to delaminate. Both matte and gloss varnishes virtually disappear after doming, but they often cause chemical reactions and delamination of the dome. On bright metallic and some large, bold surfaces, varnishes can offer a very subtle effect even after doming. Water-based varnishes can help protect some otherwise reactive surfaces. If the image or doming surface easily dissolves with oils, test a water-based coating.

Laminates: Avoid laminates when possible. Most laminates will delaminate after doming. Laminates often cause an undesirable double reflection allowing light to shine off both the laminate and the dome surface.

Print Substrate

Most non-porous print substrates such as polyester and vinyl are suitable for doming.

Liner

Supplied parts must lay flat on a flat surface to be accepted for doming. Use 90 lb., coated, lay-flat paper liner or polyester liner.

Poly-Coated Paper Liners: This is the most common liner we see. Economical and works fine for doming as long as sheets are stored flat and away from high humidity. 5-mil thickness works fine. Heavier paper liners are good as well. Consider cardboard stiffeners to keep sheets flat in shipping and double wrap bundles in plastic to help keep humidity out during shipping.

Clear Polyester Liners: It costs a little more, but it is the best liner we have found to yield consistently high-quality domes. We have had good success with FLEXcon’s 400 Poly H-9 AS liner and comparable 4-mil polyester liners from other manufacturers. Polyester liners are preferred because they lay flat even after curling and pulling. Also, a little rain or high humidity does not distort the liner. The polyester holds its shape very well after hot stamping and steel rule die cutting.

Other Liners: To be safe, send a few samples for us to evaluate. It’s a lot easier to send a sample then requiring an entire order to be transferred to a new liner.

Cutting

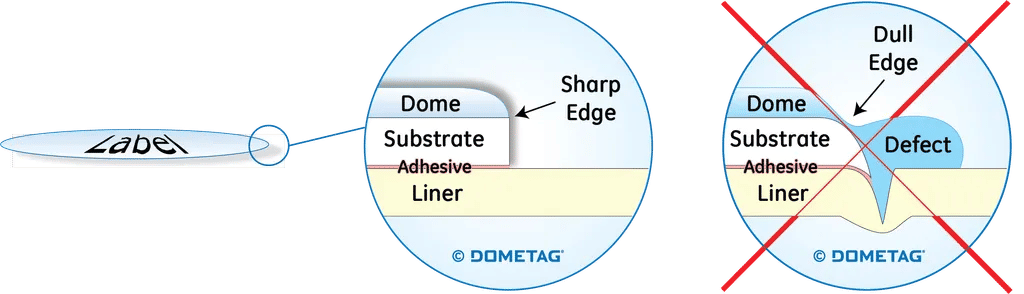

Domed labels require a straight cut with no liner nicking.

Plotter Cutter works great for doming. A little time consuming on large jobs but works great for runs of a few hundred sheets or less. Blade pressure is easy to control. Avoid cut-through on liners.

Die Cutting works great for doming, but prevent cut-through. Test to make sure the liner remains flat after cutting. Even minor bending at the edge of the part can make the piece undomable. Die cutting works well specifically because it leaves a sharp edge. Dull knives, soft liners, and incorrect pressure/depth settings can round the cut edge and increase doming errors.

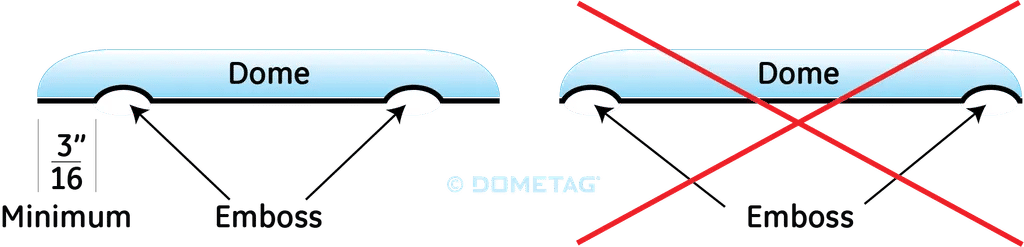

Thermal Die Cutting works okay for doming. The dome edge can have rough spots caused by vinyl melt. Most customers do not notice or do not mind this minor blemish providing the part is larger than 2”. Keep the die pressure as light as possible to avoid embossing and distorting the liner. It’s a good idea to send sample sheets for us to test before thermal cutting the full job.

Embossing: Embossing creates a great effect with metallic print surfaces. Embossing on non-metallic usually disappears after doming and can complicate the doming process. Keep embossing away from the edge of the part to prevent the emboss from acting like a wall stopping the dome before it flows to the edge of the part. After embossing, the sheet needs to lay flat to avoid defects or additional handling charges. Send sample sheets for our review when possible.

Label Spacing

Allow a minimum of 1/8″ between parts to reduce defects. Occasionally the urethane can overflow from one part into adjacent parts. If the parts are too close together, the entire sheet can be lost from a single overflow. The larger the part, the more space between parts.

Sheet Size

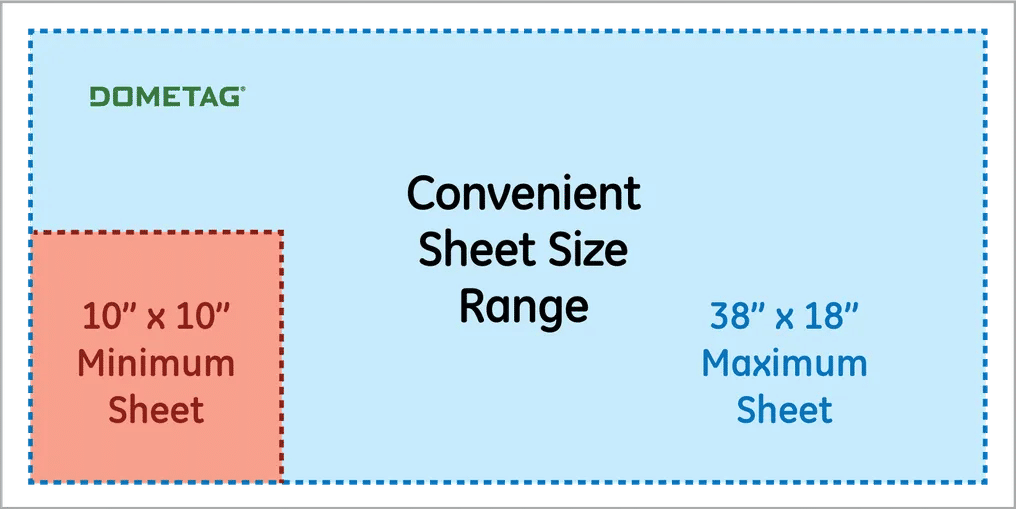

Convenient Sheet Sizes: Most any size sheet from 10″ x 10″ to 38″ x 18″ is convenient for us to work with. Additional fees may be necessary for small sheets, strips and individual pieces

Maximum Sheet Size: The maximum convenient sheet size is 38″ x 18″. We can usually accommodate other sizes, but there may be an additional handling fee. Let us know your requirements to verify if your size can be done.

Minimum Sheet Sizes: 10” x 10” is our minimum sheet size. The smaller the sheet size the more handling we have.

See additional details in the HELP – File Preparation section.