Dome

The unique dome label shape is created by pouring Clear liquid polyurethane (urethane) onto a flat label. The precisely measured volume of urethane flows to the edges of the label forming a bubble of urethane specific to the label contours. The label is kept level for approximately 12 hours while the urethane cures to a flexible, resilient and durable bubble. The result is a domed label.

Domed Label Options

DomeTag offers two different urethanes for domed labels: Flexible and Extra Flexible. Flexible urethane is the ideal choice for domed labels that are applied to flat surfaces and is our most popular urethane. Extra Flexible urethane is primarily used when applying domed labels to curved surfaces. Both Flexible and Extra Flexible urethane have a smooth surface that is resilient to impacts and allows the clear bubble dome to dent and absorb impact to rebound to its original shape. The basic chemistry, durability and guarantee are the same for both dome label options.

Domed Label Properties

Once the polyurethane dome has cured, it is: optically clear, flexible, abrasion resistant, and chemically inert. The dome label has excellent UV resistance such that it will maintain its gloss and clarity even after years of outdoor exposure.

Domed Label Thickness and Edge

Domed labels have a thickness of about 1/16” (0.06”–0.07” +/-.025”, 1.5–1.8 mm +/- 0.6 mm). Smaller domes (3/4” or less) tend to be on the thicker end of this range and domes produced with Extra Flexible polyurethane tend to be on the thinner end of the range. The natural flow of the uncured, liquid urethane determines the ultimate thickness required for production, which leaves little control over the thickness of the finished dome.

Smaller domes tend to be slightly thicker.

Note Beveled edge on domes.

Domed Label Size

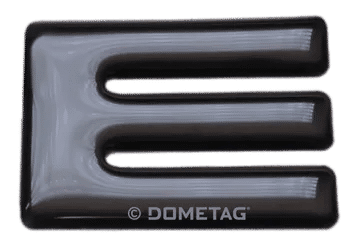

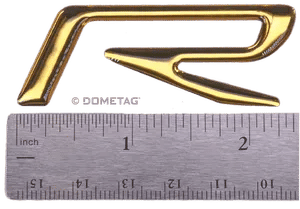

The smallest domes we produce are 0.3”x 0.3” (7.6 mm x 7.6 mm). The largest domes are 8’ x 8’. When doming unique shapes, such as individual domed letters, the smallest stroke thickness can be as small as 0.2” (5 mm). The preferred corner radius is 0.1” (2.5 mm) or larger. Remember that the radius is half the diameter of the curve meaning that a 0.1” radius has a diameter of 0.2”. Sharper corner radius’s can be domed but may require additional cost.

Domed Labels can be made in all sizes.

0.25″ minimum width on scripted domes.

Polyurethane vs Epoxy Domes

DomeTag uses premium-grade polyurethane that withstands brutal outdoor extremes unlike inferior epoxy that will lose gloss, yellow, harden, crack, shrink and curl over time. Inferior epoxy is commonplace on cheap products and is typically the cause for labels falling off and discoloring. Unfortunately, the difference between epoxy domes and urethane dome is not easy to spot when they are new. In fact, epoxy domes and urethane domes look the same for about one month before the epoxy begins to change. The shrinkage of epoxy causes labels to curl and lift the edges such that the label peels up from the mounting surface. Epoxy domed labels that fall off may appear to be caused by inferior adhesive when the real cause is inferior doming material. DomeTag’s polyurethane domes deliver the best quality, appearance, and durability.

Polyurethane vs. Epoxy

Epoxy dome yellowing within one year.

Epoxy shrinks and yellows over time- choose DomeTag instead!

A simple test can be performed to verify if a dome is urethane or epoxy. By holding a torch to the test dome, an epoxy dome will turn black and start on fire whereas a polyurethane dome will liquefy and avoid holding a flame (this test should only be conducted in a laboratory with proper ventilation and handling equipment). The increased flammability of epoxy creates a fire hazard that increases liability and product labeling requirements. DomeTag has the testing facilities to verify the material being used on domed labels. Feel free to contact us for help determining the material used for a competitor’s dome.

Dome Label Urethane Specifications

Durometer (measurement of hardness): Flexible: 70–82 Shore DO; Extra Flexible 45-55 Shore DO

Operating temperature: -40° F to +140° F (-40° C to +60° C). No effect from several hours exposure at 300° F (149° C). No effect from split-second exposure to direct flame from propane torch. Sustained exposure to direct flame (1500° F/ 816° C) will liquefy the doming material, but avoids holding a flame unless exposed to continuous extreme temperature.

Dome Label Outdoor Durability: It has been laboratory tested to withstand the equivalent of three years of Florida sunlight in a salt-water mist without any shrinkage, yellowing, or deterioration. Passed 1,500 hours QUV exposure. Passed 1,500 hours Xenon Arc Weather meter at 2,900 kj/m2. Passed 113,000 Langleys – Outdoor Florida Weathering (exposure to direct weather 5° from horizontal facing South).

Dome Label Chemical Resistance: No effect from fresh or salt water; no effect from moderate to weak acids and alkali; no effect from alcohols (e.g. methanol); glycols and glycol ethers (e.g. ethylene glycol) acceptable, but some swelling may occur; aromatic and aliphatic hydrocarbons (e.g. benzene and toluene) may cause some loss of gloss and swelling; keytones, esters, and chlorinated hydrocarbons may cause some loss of gloss and swelling.

Regulations: DomeTag’s polyurethane is in compliance with the following Directives:

• RoHS Directive 2002/95/EC (RoHS restricts the use of hazardous substances in electronically related items.)

• ELV Directive 2000/53/EC (ELV restricts the amount of hazardous waste as it relates to vehicles and vehicle by-products.)

• CE Directive 88/378/EEC (CE ensures that the toys are safe for children, and applies the EN 71-3 standard.)

• UL Directive 94 HB 40 (This is a flammability test.)

• JIG-101 ED 2.0 (This is a guide of substances that must be disclosed if present. Domed labels polyurethane doesn’t contain any of the substances listed in this guide.)